FOR OVER 75 YEARS!

Quality is our passion.

We have been dedicated to our customers

by meeting and exceeding, their

stainless steel tubing needs!

Ornamental Tubing

Stainless Steel

Tubing

Ornamental ASTM A554

Tubing

QS Certified

#0009870

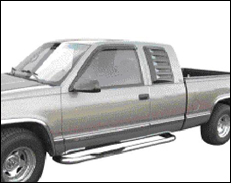

Some ornamental tubing has to be more than just ornamental.

Tubing which is not only ornamental, but also meets

stringent

standards for

engineering and performance

excellence for the

automotive,

leisure and

construction

industry.

United

Industries has produced stainless steel tubing to ASTM

A554

ornamental specifications

for over 35 years.

Material is

produced

for a

wide range of

applications including

tubing for mirror

bracket

arms, boat rails and

ladders,

washroom grab

bars,

swim

pool rail

goods,

medical

equipment, automotive

step bars and

grille guards

among many others. All

300

series austenitic tubing is

provided

in

the

surface finish

and

packaging requirements provided

by our

customers.

Manufacturing

All

ornamental ASTM A554 tubing is produced using raw material

from

only our approved steel

suppliers with specific

Rockwell and

surface

finish

requirements.

United

Industries slits the wide coils to

specific OD

widths in-house.

Tube production begins with high

quality roll form

tooling that

minimizes marking,

then TIG

(Tungsten

Inert Gas) welding

or laser

welding, ID and OD weld bead

conditioning, final

sizing,

cut to length, deburring, specified

polishing,

surface finish

protection and packaging

for

shipment. All

manufacturing is

done completely

inline keeping work in process to a

minimum, which

reduces

material handling.

Polishing

United

Industries offers a wide variety of mechanical surface

finishes ranging from a 180 grit satin commonly used

for washroom

grab bars to a

super buff finish on

automotive

accessory tubing.

United

Industries also

offers

the highest

quality as welded

surface

for

our

customers who

mechanically

polish the tubing

themselves or

have it

electropolished. United Industries’ in-house

sample

electropolish testing

tank

ensures the

surface condition required

for

these

applications.

Quality

/ Testing

All

testing required by ASTM A554 and our customers, based on

fabrication and surface finish requirements, are

done inline by the

tube mill

operator. Destructive

tests are

performed at regular

intervals

and tubing

is 100%

inline eddy

current tested.

Plug gauges

are

utilized

inline and made to

dimensions provided by our

customers

if the tubing is

mandrel bent.

Mechanical

polishing

compounds and

equipment are

constantly

monitored

using polished sample tubes.

Product

Delivery

A

wide range of transportation alternatives are available

for fast

deliveries across

North America. United

Industries’

JIT

manufacturing

capabilities enable fast order

turnaround due to

changing

customer

requirements.

Our Commitment

Solid and Stable

United Industries history, reputation, future and

mission is

to manufacture all of our welded stainless

steel

tubing to the

standard of

excellence.